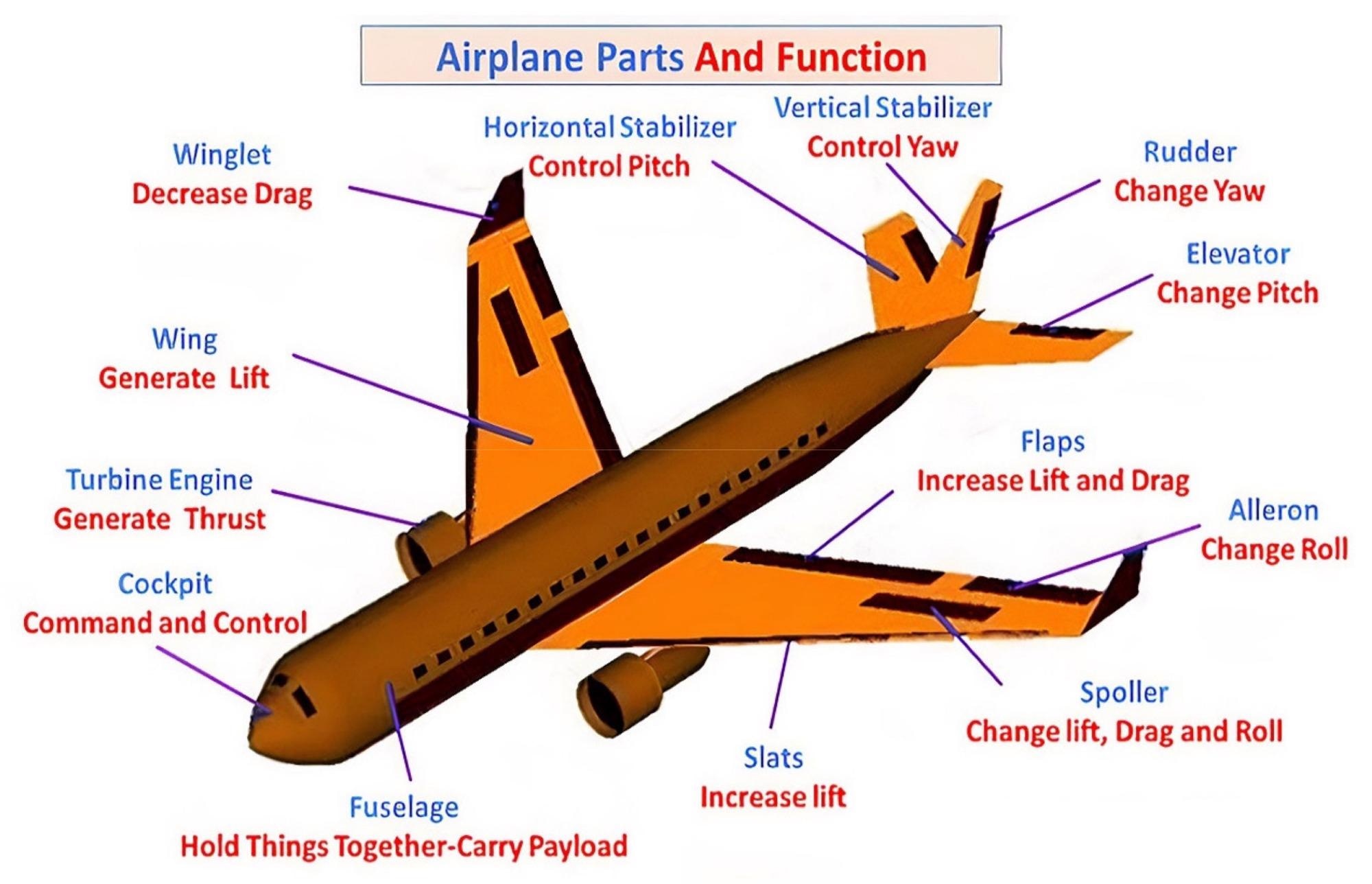

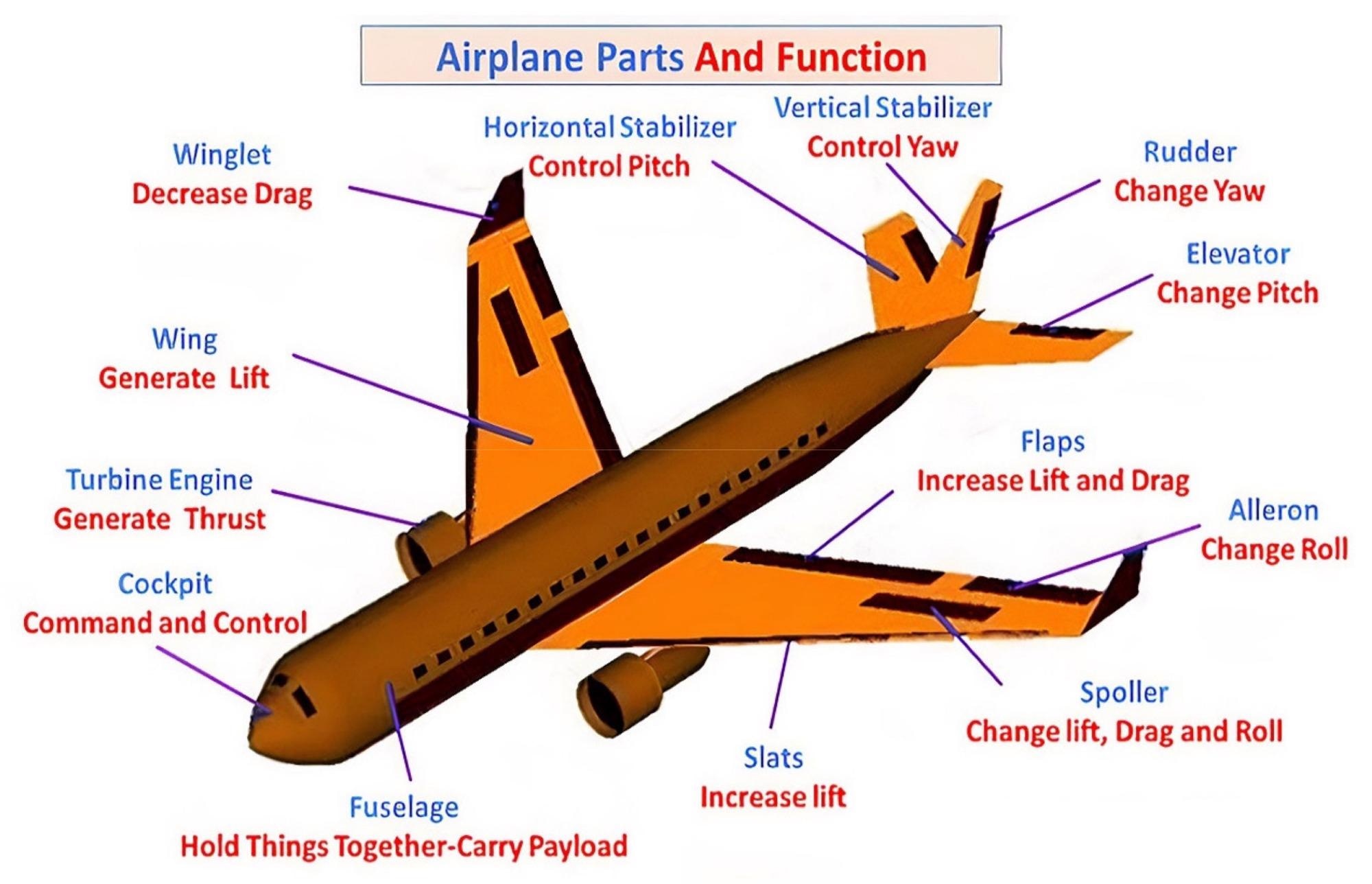

Structural Parts Of Aircraft - If you have ever sat over a wing during a flight, you'll have noticed a fair amount of movement of different panels and parts of the wing. Each of these moving parts has a name and performs a specific function.

They are called flight control surfaces. Examples of spacecraft secondary products are power sources—such as solar panels, batteries, and fuel cells—and photographic, radar, infrared, and other types of sensory devices for military intelligence gathering and for civil use including meteorology and remote sensing of the Earth.

Structural Parts Of Aircraft

Additionally, for crewed spacecraft there are special-purpose radars for docking in space or landings; environmental-control systems; cabin instrumentation and displays; space suits; and galleys, water dispensers, and waste-management systems designed for operation under microgravity conditions. The desired final shape, in terms of both external appearance and the internal structure required for adequate strength, of a component made of composite materials can be arrived at by a variety of means.

Flight Control Surfaces

The simplest is the laying up of fiberglass sheets, much as is done in building a canoe, impregnating the sheets with a resin, and letting the resin cure. More sophisticated techniques involve fashioning the material into specific shapes by elaborate machinery.

Some techniques require the use of male or female molds or both, while others employ vacuum bags that allow the pressure of the atmosphere to press the parts into the desired shape. While the basic principles of flight that the Wright brothers applied still pertain, there have been enormous changes over the years to the means by which those principles are understood and applied.

The most pervasive and influential of these changes is the wide variety of applications of computer technology in all aspects of aviation. A second factor has been the widespread development of the use of composite materials in aircraft structures.

While these two elements are the results of advances in engineering, they are also indirectly the product of changing social and legal considerations. Aircraft made of wood and fabric were difficult to maintain and subject to rapid deterioration when left out in the elements.

Other Secondary Systems

This, plus the need for greater strength, led to the use of metal in aircraft. The first general use was in World War I, when the Fokker aircraft company used welded steel tube fuselages, and the Junkers company made all-metal aircraft of dual tubing and aluminum covering.

During the late 1940s, interest developed in fiberglass materials, essentially fabrics made up of glass fibers. By the 1960s, enough materials and techniques had been developed to make more extensive use possible. The term "composite" for this method of construction indicates the use of different materials that provide strength, light weight, or other functional benefits when used in combination that they cannot provide when used separately.

They usually consist of a fiber-reinforced resin matrix. The resin can be a vinyl ester, epoxy, or polyester, while the reinforcement can be any one of a variety of fibers, ranging from glass through carbon, boron, and a number of proprietary types.

Modern aerospace vehicles may have dozens of separate subsystems other than propulsion and avionics. The number of individual product items is too lengthy for even a catalog listing, but a sampling of important products illustrates the breadth of the secondary product line.

How Flaps Work

Flaps move symmetrically, reward and downwards. As a result, the surface area of the wing, as well as its camber, is increased. This means that the wing produces more lift, staying airborne at much slower speeds.

The secondary product line of the aerospace industry comprises the numerous onboard subsystems required by the designs of the various flight vehicles. Propulsion and avionics are the two most important secondary systems. The industry's tertiary product line includes those ground-based items necessary for the support of flight vehicles.

Another major group of tertiary aerospace products are ground radars and antennas with their associated data-processing systems. This equipment is employed for air traffic control, detection and tracking of potentially hostile flight vehicles, remote command of missile guidance, interception guidance of air-defense aircraft, and tracking of spacecraft.

Air traffic control systems are produced by companies such as IBM, Boeing, and Lockheed Martin in the United States and GE Ferranti and Thales ATM in Europe. Harris Corporation and Raytheon, among others, contribute ground-based radar and data-processing equipment.

Secondary And Tertiary Aerospace Systems

A third important group of tertiary products comprises automatic checkout equipment for complex aircraft, space vehicles, and missiles. Three large aerospace engine manufacturers have product lines that range from small turboprop power plants to the highest-thrust turbofans: General Electric Aircraft Engines and Pratt & Whitney (a subsidiary of United Technologies) in the United States and Rolls-Royce in Britain.

A number of smaller firms produce small-to-medium-sized turbofans, as well as turboprop and turboshaft engines. Examples are SNECMA and Turboméca in France; the DaimlerChrysler subsidiary MTU Aero Engines in Germany; Volvo Flymotor in Sweden; FiatAvio in Italy;

Aero Engine Corporation in Japan; Williams International, Rolls-Royce Allison, Textron Lycoming, and Honeywell in the United States; and Pratt & Whitney Canada. Notable manufacturers from the former Soviet Union are Klimov, Kuznetsov, Aviadvigatel, and Saturn. Complementing and enhancing the results of the use of computers in design is the pervasive use of computers on board the aircraft itself.

Computers are used to test and calibrate the aircraft's equipment, so that, both before and during flight, potential problems can be anticipated and corrected. Whereas the first autopilots were devices that simply maintained an aircraft in straight and level flight, modern computers allow an autopilot system to guide an aircraft from takeoff to landing, incorporating continuous adjustment for wind and weather conditions and ensuring that fuel consumption is minimized.

Use Of Computers

In the most advanced instances, the role of the pilot has been changed from that of an individual who continuously controlled the aircraft in every phase of flight to a systems manager who oversees and directs the human and mechanical resources in the cockpit.

The use of composite materials opened up whole new methods of construction and enabled engineers to create less expensive, lighter, and stronger parts of more streamlined shapes than had previously been feasible with wood or metal.

Like the computer, the use of composites has spread rapidly throughout the industry and will be developed even further in the future. Rocket engines are used as power plants for guided missiles and space launch vehicles and for maneuvering and maintaining the position of spacecraft.

Because of the requirement for long storage, the great majority of missiles are powered by solid-fuel systems. Such systems are disadvantageous in that their thrust per quantity of fuel consumed is relatively low and that, once ignited, they cannot be turned off.

Early Technology

Consequently, most space launch vehicles requiring control and multiple starts employ liquid-propellant systems as main engines for the primary stages but use large solid-fuel rockets as boost-stage auxiliaries for additional thrust in the initial phase of launch.

Among American companies engaged in the production of rocket motors are Boeing's subsidiary Rocketdyne, Thiokol, Kaiser Marquardt, and Aerojet General. In Europe, SEP, a division of SNECMA, predominates. Russian systems are produced by Energomash and Kuznetsov.

Since the mid-1960s, computer technology has been continually developed to the point where aircraft and engine designs can be simulated and tested in myriad variations under a full spectrum of environmental conditions prior to construction. As a result, practical consideration may be given to a series of aircraft configurations, which, while occasionally and usually unsuccessfully attempted in the past, can now be used in production aircraft.

These include forward swept wings, canard surfaces, blended body and wings, and the refinement of specialized airfoils (wing, propeller, and turbine blade). With this goes a far more comprehensive understanding of structural requirements, so that adequate strength can be maintained even as reductions are made in weight.

Final Thoughts

The social issues are manifold and include the increasing global interdependence of business, the unprecedented political revolutions in every part of the world, and the universal human desire for travel. In addition, concerns have grown about the environmental impact of airplanes, especially in regards to the burning of fuel and its contribution to global warming.

All these issues come at a time when fuel prices have increased. As a result, both computers and composite materials are necessary to create lighter, stronger, safer, more fuel-efficient aircraft. The legal issues are equally complex, but for the purposes of this section revolve around two elements.

The first of these is that the design, test, and certification of an aircraft has become such an extraordinarily expensive project that only the most well-funded companies can undertake the development of even relatively small aircraft.

For larger aircraft it is now common practice for several manufacturers, often from different countries, to ally themselves to underwrite a new design. This international cooperation was done most successfully first with the Anglo-French Concorde supersonic transport and has since been evident in a number of aircraft.

What Are Flaps On Aircraft?

A component of this process is the allocation of the production of certain elements of the aircraft in certain countries, as a quid pro quo for those countries not developing indigenous aircraft of a similar type.

Avionics includes all instruments, sensors, and electronic equipment and the electrical systems that link them to each other and to aerospace vehicle-control systems. It encompasses the functional equipment for guidance, navigation, and communications. A modern airline transport can contain more than 1,000 sensors and "black boxes."

The latter are metal or plastic housings in which electronic and electrical components are grouped to perform specific functions. (They differ from flight recorders, also dubbed black boxes, which record the performance and condition of an aircraft in flight.) For advanced military aircraft, avionics represents as much as 35 percent of the total cost;

when radar and other electronic and electro-optic system adjuncts are included, the value can exceed 50 percent. For some spacecraft, the equivalent equipment can reach 70 percent of the cost. Leading manufacturers of avionics systems include Rockwell Collins, Honeywell, and Litton in the United States and Thales Avionics in France.

Use Of Composite Materials

For reasons of availability, low weight, and prior manufacturing experience, most early aircraft were of wood and fabric construction. At the lower speeds then obtainable, streamlining was not a primary consideration, and many wires, struts, braces, and other devices were used to provide the necessary structural strength.

Preferred woods were relatively light and strong (e.g., spruce), and fabrics were normally linen or something similarly close-woven, not canvas as is often stated. The second legal element is that the potential of very large damages being awarded as a result of liability in the event of a crash has forced most aircraft companies to cease the manufacture of the smaller types of personal aircraft.

The reason for this is that the exposure to damages from a large number of small single-engine planes is greater than the exposure from the equivalent market value of a few larger planes, because the larger planes generally have better maintenance programs and more highly trained pilots

. The practical effect of this has been an enormous growth in the home-built aircraft industry, where, ironically, the use of computers and composites have effected a revolution that has carried over to the commercial aircraft industry.

Wing Tips

Wings are more than two flat panels sticking out of the side of the aircraft, there is a surprising number of parts of a wing, and each performs a vital task. The next time you fly, you'll know what each part does and the effect it has.

Want to learn more about airplane parts and principles of flight? Why not check out our free ultimate guide to becoming a pilot. If we stand at the rear of the aircraft, we can see the backs of the wings.

These are called the trailing edge. The trailing edges of an airplane wing are usually very thin compared to the leading edge. Flaps are large panels located on the trailing edge of the wing that are used to increase the size and shape of the wing, as well as the chord line.

They enable the aircraft to fly slower and give the pilots a better view for landing. They are also used for takeoff. The use of composite materials, similarly assisted in both design and application by the use of computers, has grown from the occasional application for a nonstructural part (e.g., a baggage compartment door) to the construction of complete airframes.

What Are Slats?

These materials have the additional advantage in military technology of having a low observable (stealth) quality to radar. Secondary products for missiles and space launch vehicles include the many sensors and control mechanisms associated with their guidance and target-acquisition functions, small rocket motors, and weapons elements (in the case of missiles).

For both missiles and launch vehicles, however, avionics related to navigation and control represent the highest-value elements. The coincident arrival of the new technology in computers and composite materials influenced commercial air transportation, where aircraft larger than the Airbus A380 and faster than the Concorde are not only possible but inevitable.

In the field of business aircraft, the new technologies have resulted in a host of executive aircraft with the most modern characteristics. These include the uniquely configured Beech Starship, which is made almost entirely of composite materials, and the Piaggio Avanti, which also has a radical configuration and employs primarily metal construction but includes a significant amount of composite material.

Commercial air transports are using composite materials in increasing amounts and may ultimately follow the pattern of the military services, where large aircraft like the Northrop B-2 are made almost entirely of advanced composite materials. The engine(s), or powerplant, of an aircraft creates the thrust needed for the plane to fly.

Tertiary Systems

Generally speaking, there are two types of aircraft engines, reciprocating and turbine. With reciprocating engines, air flows into the engine, is compressed and mixed with fuel and an electric spark to combust, with exhaust gases leaving the back of the engine through the manifold.

The engine spins the propeller which then creates thrust to move the plane forward. Alternatively, with a turbine engine, the action of compressing air, mixing with fuel, ignition and exhaust are similar but occur inline. In this case the power is generated by the air being exhausted from the engine.

Ailerons move up and down to change the chord line at the end of each wing. When the cord line is altered, this changes the airflow going over the wing. When an aileron is up, its corresponding wing is pulled down.

When you stand sideways on most aircraft wings, you'll notice that the upper surface is curved. The depth of the curve is called camber. A greater camber means a more pronounced curve in the wing's top surface.

Leading Edge

Many of the companies involved make lines of aerospace products that are variants of their products for other industries. An example is Goodyear Tire & Rubber, which supplies tires for aircraft as well as land vehicles.

Other secondary-product companies were at one time producers of primary systems such as engines. Examples are the French firm Messier-Dowty (a subsidiary of SNECMA) and the American firm Goodrich, both of which were small-engine manufacturers before becoming major suppliers of landing gear.

As speeds advanced, so did structural requirements, and designers analyzed individual aircraft parts for both strength and wind resistance. Bracing wires were given a streamlined shape, and some manufacturers began to make laminated wood fuselages of monocoque construction (stresses carried by the skin) for greater strength, better streamlining, and lighter weight.

The 1912 record-setting French Deperdussin racers, the German Albatros fighters of World War I, and the later American Lockheed Vega were among the aircraft that used this type of construction. Spoilers increase drag over the wing.

If you are familiar with flight principles, you'll know that drag makes level flight harder. If you increase the drag on only one wing, it will descend, creating a rolling motion. Landing gear is located under the belly of the plane consisting of a wheel and strut to soften impact with the ground and may be retractable into the fuselage.

Tricycle type wheels are common for general aviation with one wheel at the front and two behind or the reverse for tailwheels with two wheels at the front of the plane and one under the tail.

An aircraft's propeller(s) are airfoils, similar to a wing, installed vertically to create thrust to drive the plane forward. Attached to the engine, they spin quickly, creating lift from the pressure difference they create, only instead of this lift causing the plane to move upwards, it drives the plane forward creating thrust.

This thrust and forward motion in turn causes air to pass over the wings, creating the vertical lift. Let's start outside the aircraft, facing the airplane sideways at the very end of the wing. This section is called the wingtip.

The wingtips are the furthest point of the wing from the aircraft's body.

aircraft structural components, aircraft frame structure, structures of an aircraft, primary structure of aircraft, airplane structure, plane frame structure, aircraft structure terminology, components of an aircraft